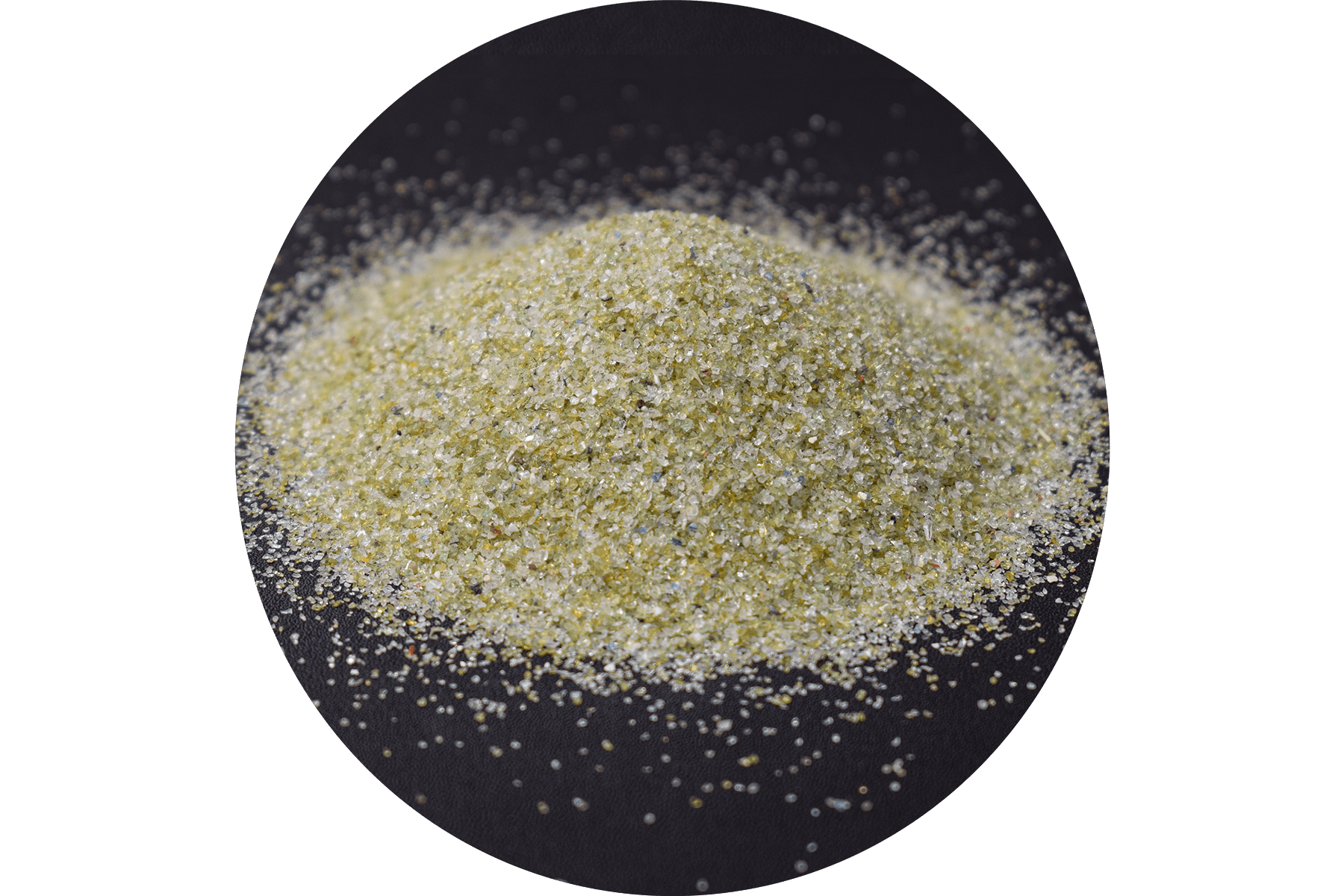

CRUSHED GLASS

THE PERFECT GENERAL PURPOSE ABRASIVE

Our Crushed Glass blast media is manufactured from 100% recycled bottle glass. Crushed bottle glass is a solid, general purpose abrasive – its economical, eco and operator-friendly and offers many advantages over traditional abrasives such as coal and copper slag. ESCA bottle glass works great in vapor, dustless and dry-blast equipment.

Crushed Glass blast media is classified as a semi-hard abrasive. It’s aggressive enough to remove many coatings and paints. With the right technique and approach, it can also be used on fiberglass boat bottoms, some wood materials, commercial masonry, and other sensitive substrates that harder abrasives would ruin.

Not too hard AND Not too soft

Our best analogy is this: When you drop a glass bottle it will shatter. However, a bottle made of JETMAG would just bounce off the floor. Although glass will abrade the surface you are working on, you can control its impact because of this “shattering” feature. It is possible to achieve a range of finishes with glass, from very light textures to paint-ready profiles. Due to its translucent nature, crushed glass will also deliver a whiter metal finish than many other sandblasting abrasives.

- Automotive depainting

- Light-medium rust removal

- Graffiti removal

- Commercial restoration

- Equipment maintenance

- Log homes, boat bottoms, pool cleaning

- Paint Stripping

- Coating Removal

- Severe Fire Damage restoration

- Parts Cleaning

- Non-hazardous, non-toxic and inert

- If Dry Blasting, dust is translucent – significantly improving visibility and productivity when compared to using traditional hard abrasives like coal slag or silica sand

- Free Project Support: Consumption and production rates, scheduling, application recommendations

- Shelf Life: Unlimited when stored indoors

- Non-Hazardous / Non-Toxic

- No solvents or caustic ingredients – simplifies and reduces waste disposal costs

- Can perform wet/ “dustless” or dry cleaning

- Interior or Exterior projects

- Landscape-safe

- Packaging: 50 lb bags

- Full Skid: (56) bags or 2800+ lbs

- Supersacks: 3086 lbs

- No minimum order at any of our locations: Hatfield, PA; Grand Rapids, MI; Greensboro, NC

- Mix and Match skids of different grades OR medias available at no extra charge

- Logistics: We can deliver to virtually any location, including construction sites, residential addresses, military complexes, nearby terminals.

- Need rush service, lift gate, call ahead, or appt? No problem!

- All Major credit cards accepted

- Free Project Support: Consumption and production rates, scheduling, application recommendations

- Ready to Order? Contact us now!